Steel on its own is strong — but when you add the right elements, it becomes something extraordinary. Think of alloying elements as the “secret ingredients” in a recipe. A small change can completely transform the final result.

What Are Alloying Elements in Steel?

Alloying elements are materials like chromium, nickel, molybdenum, manganese, and vanadium that are added to steel during production. These elements don’t just sit there — they actively change how the steel behaves. By adjusting the composition, manufacturers can fine-tune strength, hardness, corrosion resistance, and toughness.

Boosting Strength and Hardness

Elements like carbon and manganese increase strength and hardness. This makes alloy steel ideal for heavy machinery, construction equipment, and load-bearing structures. It’s like reinforcing concrete with steel bars — the added element provides extra muscle.

Improving Corrosion and Heat Resistance

Chromium and nickel are famous for enhancing corrosion resistance. That’s why stainless steel contains high levels of chromium. Molybdenum helps steel handle high temperatures without losing strength, making it perfect for pressure vessels and energy projects.

Enhancing Toughness and Durability

Some alloying elements improve impact resistance and durability. Nickel, for example, helps steel remain tough even in low temperatures. This balance between strength and flexibility prevents cracking under stress.

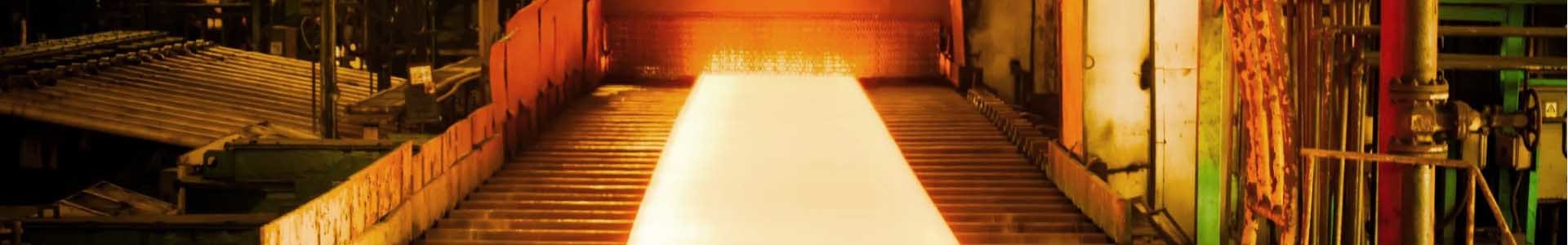

Why Dongte Metal Focuses on Precision Alloy Control

At Dongte Metal, we carefully control alloy composition to ensure consistent performance across every batch. Our alloy steel products are engineered to meet demanding industrial standards, whether for construction, manufacturing, or heavy industry applications.

At Dongte metal, we have steel plate, steel coil, steel pipe, rebar, steel profile, wire rod, steel round bar, ductile iron pipe, steel sheet pile, brass.