Seamless Steel Pipe vs. Welded Pipe: Which Is Better for High-Pressure Systems?

When you’re working with high-pressure pipelines, choosing the right steel pipe can feel a bit like choosing the right backbone for your system — it has to be strong, dependable, and built for the job. Two of the most common options are seamless pipes and welded pipes, and each brings something different to the table.

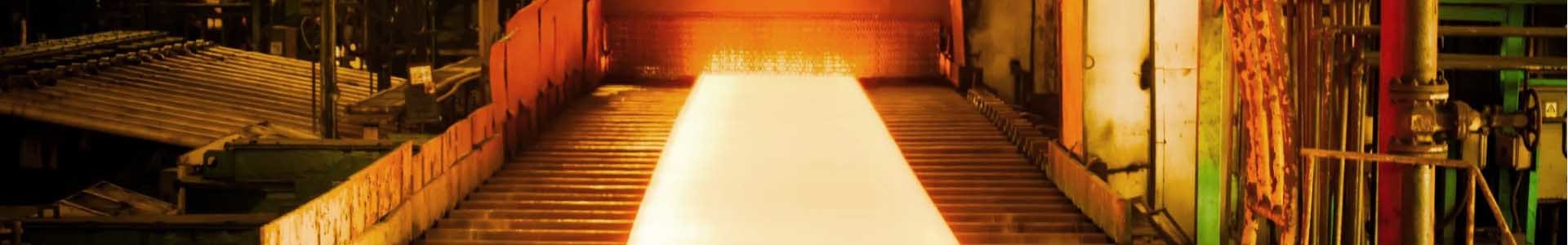

Seamless Pipes — Built for Strength and Stability

Seamless pipes are produced without a welded seam, which makes the structure uniform from end to end. That smooth, uninterrupted body gives them excellent resistance to pressure and stress. In demanding environments — like oil, gas, or chemical systems — seamless pipes often perform like quiet heroes, handling extreme loads with fewer weak points.

Welded Pipes — Reliable and Budget-Friendly

Welded pipes are made by rolling and joining steel plates, leaving a visible weld line. While they may not match seamless pipes for ultra-high-pressure tasks, they work great in moderate-pressure applications. They’re also more economical, easier to customize in larger sizes, and widely used in construction, water systems, and structural projects.

Which One Should You Choose?

Here’s a simple rule of thumb: if your system faces intense, continuous pressure, seamless is usually the safer bet. If your needs are more cost-driven and the pressure level is moderate, welded pipes offer solid value. Think of it as choosing between heavy-duty armor and everyday work gear — both useful, just in different situations.

Dongte Metal — Your Partner in Steel Pipe Solutions

At Dongte Metal, we supply both seamless and welded steel pipes, helping buyers match the right product to the right application with confidence and technical support.

If you’re planning a high-pressure project and want professional guidance, feel free to contact us.