-

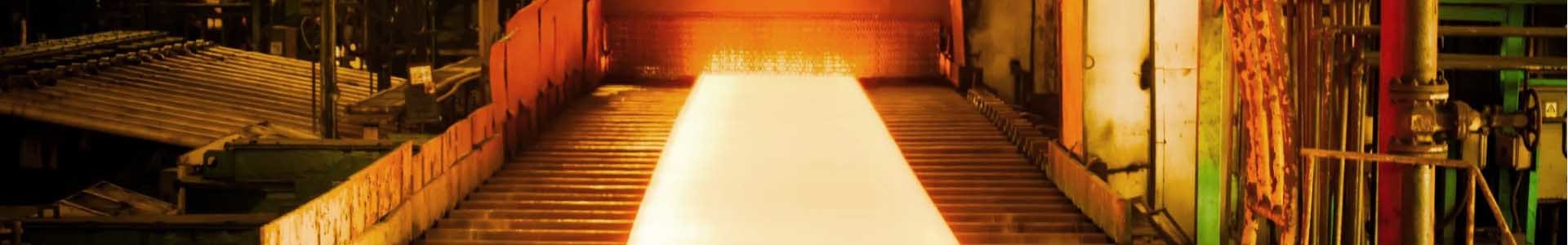

How to Reduce Production Costs When Working with Carbon Steel Materials

This article explores practical ways to lower production expenses when using carbon steel, with insights from Dongte Metal, a trusted supplier known for delivering high-quality and cost-efficient steel solutions.

Choose the Right Grade for the Job

Not all carbon steel is created equal—and that’s a good thing. Selecting the correct grade for your project can save you money from the start. For example, mild carbon steel is often perfect for general fabrication, while high-carbon steel works better for tools or wear-resistant parts. By matching the grade to your specific need, you avoid overpaying for unnecessary performance.

Optimize Your Cutting and Welding Techniques

Precision is profit. When cutting or welding carbon steel, using modern, efficient tools reduces waste and energy costs. Consider laser or plasma cutting for cleaner edges and faster processing. It’s like trimming fat from your workflow—less material loss means more savings in the long run.

Minimize Waste Through Smart Design

Small design adjustments can lead to significant cost reductions. Plan your cuts strategically to use every inch of your steel sheets or rods. Recycle leftover pieces whenever possible. Think of it as a puzzle—smart placement helps you make the most of every piece.

Partner with a Reliable Supplier

A dependable supplier can make or break your cost efficiency. Dongte Metal offers premium carbon steel with consistent quality, reducing the risk of production errors or rework. Plus, our competitive pricing and flexible supply chain solutions help you stay within budget without compromising performance.

In Dongte, We have carbon steel coil, carbon steel plate, carbon steel coil, carbon steel pipe.

Related news

Contact

Phone : +86 18954546689

Email : sales03@zgdtsteel.com

WhatsApp : +86 18954546689

Wechat : 18954546689

We use optional cookies to improve your experience on our website, including through social media connections and to serve personalized advertising based on your online activity. If you reject optional cookies, we will only use cookies that are necessary to provide you with the service.

Privacy statement